Let’s work together

The possibilities are endless

Secondary packaging is the grouping of several individual items into a secondary container. Depending on your product this may also mean a single product into the container. Secondary packaging solutions are provided after your product has been packaged and is ready to be placed in the shipping container. With so many secondary automated packaging equipment options on the market, how do you know which one to choose?

Your solution will be based strictly on your needs. At BPA, factors such as product and package type, speed, number of recipes and pack patterns and more will be taken into consideration when determining a secondary packaging solution best for you. BPA has a diverse team of experts on hand to assist you through this process.

Products

- Gravity 100 Case Packer

- Gravity 100R Case Packer

- CubeMaster 200 Case Packer

- CubeMaster 200i Case Packer

- CubeMaster 300 Case Packer

- CubeMaster 300i Case Packer

- Gantry 100 Case Packer

- Gantry 200 Case Packer

- Gantry 200i Case Packer

- Gantry 300 Swing Case Packer

- Spider 100 Case Packer

- Spider 100i Case Packer

- Spider 200 Case Packer

- Spider 200i Case Packer

- Spider 300 Case Packer

- Spider V series

- Spider Q series

- Spider 300v Case Packer

- SnackMaster 200 Case Packer

- SnackMaster 200i Case Packer

- Wraparound 100

- Wraparound 200

- Wraparound 300

- Cartoner 100

- Cartoner 100c

- Variety Pack in Sack or Case

- Shaker-Compactor-Sealer (SCS)

- Collator 200 Semi Automatic Packing

- Bag in Bag Solutions - Jongerius Hanco

- Strip Sachet Machine - Jongerius Hanco

For these industries:

CubeMaster 300 Case Packer

Top and Side Loading of Flexible Bags with an Automatic Case Packing System

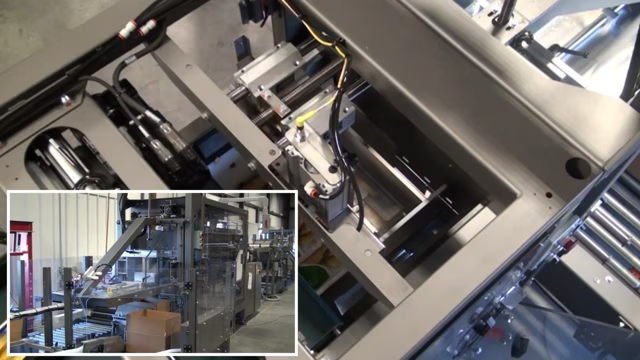

Looking for a high speed case packing system that can operate both vertically and horizontally? The CUBEMASTER 300 is quickly becoming the new standard for potato and frozen food processors using case packing of kraft, paper and poly bags.

This system is based on our CUBEMASTER 200 system, and is expanded with a horizontal pack cassette. During top loading, a flat pack cassette is lowered in front of the loading mandrel. Once in position, a pre-stacked case load is gently placed into the case. Changeovers to horizontal packing are quick and simple, after which a wide range of pack patterns can be realized. Both large 6lb / 3kg food service bags and small retails bags can be processed on the same machine, offering you great flexibility with a single system.

The CUBEMASTER 300 is available with a robust frame made from either painted carbon or stainless steel. Wash down is available in varying degrees. Is your process not yet prepared for horizontal mode? The CUBEMASTER 300 is also available as a standard vertical only packer, which you can expand with a custom designed module for future integration of a horizontal packing process.

This system is based on our CUBEMASTER 200 system, and is expanded with a horizontal pack cassette. During top loading, a flat pack cassette is lowered in front of the loading mandrel. Once in position, a pre-stacked case load is gently placed into the case. Changeovers to horizontal packing are quick and simple, after which a wide range of pack patterns can be realized. Both large 6lb / 3kg food service bags and small retails bags can be processed on the same machine, offering you great flexibility with a single system.

The CUBEMASTER 300 is available with a robust frame made from either painted carbon or stainless steel. Wash down is available in varying degrees. Is your process not yet prepared for horizontal mode? The CUBEMASTER 300 is also available as a standard vertical only packer, which you can expand with a custom designed module for future integration of a horizontal packing process.