Let’s work together

The possibilities are endless

Secondary packaging is the grouping of several individual items into a secondary container. Depending on your product this may also mean a single product into the container. Secondary packaging solutions are provided after your product has been packaged and is ready to be placed in the shipping container. With so many secondary automated packaging equipment options on the market, how do you know which one to choose?

Your solution will be based strictly on your needs. At BPA, factors such as product and package type, speed, number of recipes and pack patterns and more will be taken into consideration when determining a secondary packaging solution best for you. BPA has a diverse team of experts on hand to assist you through this process.

Products

- Gravity 100 Case Packer

- Gravity 100R Case Packer

- CubeMaster 200 Case Packer

- CubeMaster 200i Case Packer

- CubeMaster 300 Case Packer

- CubeMaster 300i Case Packer

- Gantry 100 Case Packer

- Gantry 200 Case Packer

- Gantry 200i Case Packer

- Gantry 300 Swing Case Packer

- Spider 100 Case Packer

- Spider 100i Case Packer

- Spider 200 Case Packer

- Spider 200i Case Packer

- Spider 300 Case Packer

- Spider V series

- Spider Q series

- Spider 300v Case Packer

- SnackMaster 200 Case Packer

- SnackMaster 200i Case Packer

- Wraparound 100

- Wraparound 200

- Wraparound 300

- Cartoner 100

- Cartoner 100c

- Variety Pack in Sack or Case

- Shaker-Compactor-Sealer (SCS)

- Collator 200 Semi Automatic Packing

- Bag in Bag Solutions - Jongerius Hanco

- Strip Sachet Machine - Jongerius Hanco

For these industries:

CubeMaster 300i Case Packer

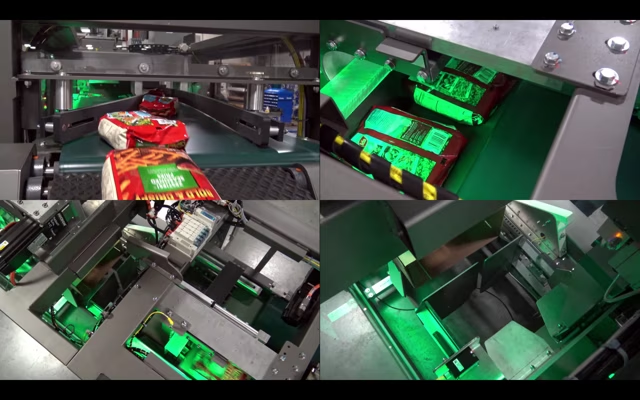

Top and Side Loading of Flexible Bags with an Integrated Case Erector

The CUBEMASTER 300i is similar to the CUBEMASTER 300i case packing system that operates both vertically and horizontally. The major differentiator of the CUBEMASTER 300i is the integrated BPA robotic case erector. This optimizes floor space utilization, and often eliminates the need for costly mezzanines. The case packer itself operates similar as the CUBEMASTER 300i, providing for a high throughput and the tightest case tube utilization in the global packing industry.

The integrated robotic case erector automatically loads a predetermined number of blank cases into the system. Once this is done, the conveyor moves the stack to its pick position, making room for the operator to load another stack. This boosts efficiency, just as the fact that the stacks do not have to be perfectly square. Prior to picking the first blank case, the top four cases are automatically squared with two cylinders. All in all, this is a unique erecting method that allows for cases to be formed with either the short or long side leading.

The integrated robotic case erector automatically loads a predetermined number of blank cases into the system. Once this is done, the conveyor moves the stack to its pick position, making room for the operator to load another stack. This boosts efficiency, just as the fact that the stacks do not have to be perfectly square. Prior to picking the first blank case, the top four cases are automatically squared with two cylinders. All in all, this is a unique erecting method that allows for cases to be formed with either the short or long side leading.