Vamos trabalhar juntos

As possibilidades são infinitas

A embalagem secundária é o agrupamento de vários itens individuais em um contêiner secundário. Dependendo do seu produto, isso também pode significar um único produto no contêiner. As soluções de embalagem secundária são fornecidas após o produto ter sido embalado e estar pronto para ser colocado no contêiner de remessa. Com tantas opções de equipamentos de embalagem secundária automatizada no mercado, como saber qual escolher?

Sua solução será baseada estritamente em suas necessidades. Na BPA, fatores como tipo de produto e embalagem, velocidade, número de receitas e padrões de embalagem, entre outros, serão levados em consideração ao determinar a melhor solução de embalagem secundária para você. A BPA tem uma equipe diversificada de especialistas à disposição para ajudá-lo nesse processo.

Produtos

- Empacotadora Gravity 100

- Empacotadora Gravity 100R

- CubeMaster 200 Empacotadora

- CubeMaster 200i Empacotadora

- CubeMaster 300 Empacotadora

- CubeMaster 300i Empacotadora

- Gantry 100 Empacotadora

- Gantry 200 Empacotadora

- Gantry 200i Empacotadora

- Gantry 300 Swing Empacotadora

- Spider 100 Empacotadora

- Spider 100i Empacotadora

- Spider 200 Empacotadora

- Spider 200i Empacotadora

- Spider 300 Empacotadora

- Série Spider V

- Série Spider Q

- Spider 300v Empacotadora

- SnackMaster 200 Empacotadora

- SnackMaster 200i Empacotadora

- Wraparound 100

- Wraparound 200

- Wraparound 300

- Cartoner 100

- Cartoner 100c

- Pacote variado em saco ou caixa

- Shaker-Compactor-Sealer (SCS)

- Collator 200 Embalagem semi-automática

- Soluções Bolsa em Bolsa - Jongerius Hanco

- Máquina de sachês em tira - Jongerius Hanco

Para estas indústrias:

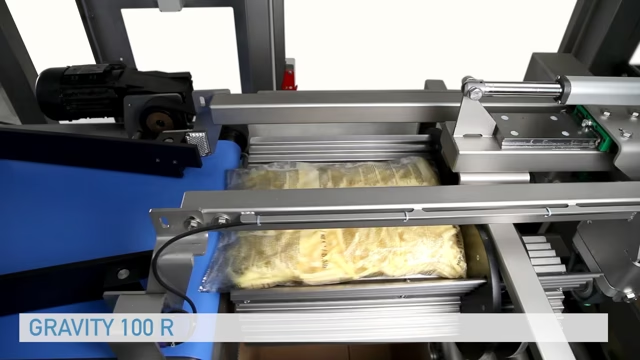

Empacotadora de caixas Gravity 100R

Carregamento superior de alta velocidade de sacos flexíveis em caixas com um sistema automático de empacotamento de caixas

Esse robusto e simples cavalo de batalha contém tudo para aumentar a produção de carregamento superior. Seus rotores foram escolhidos para depositar sacos flexíveis em caixas e permitir que a máquina embale uma grande variedade de padrões de embalagens em alta velocidade. As velocidades de produção são aumentadas porque os ajustes do tamanho da caixa e do saco são todos automatizados, eliminando também os erros do operador. Seu design aberto proporciona uma visibilidade excepcional de todo o processo de embalagem. Isso permite o treinamento rápido e fácil dos operadores.

Como cada ambiente de produção é único, cada organização exige uma solução sob medida. Desafie-nos e coloque nossos especialistas à prova para desenvolver a solução que se adapta ao seu processo como uma luva.